Quick Link

Find Products

Contact us

News

Home > News > What is direct metal deposition?

What is direct metal deposition?

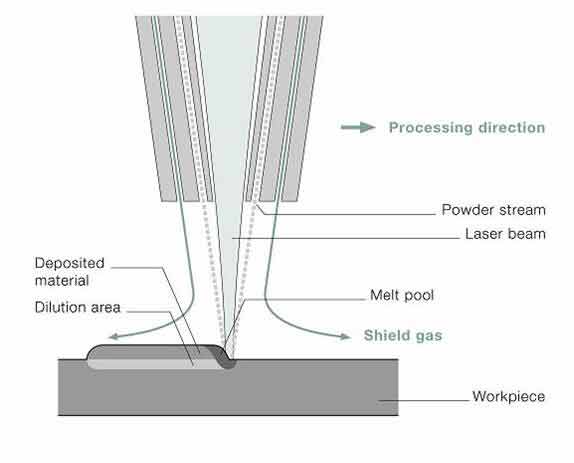

Direct Metal Deposition(DMD) is arapid prototyping process which can output melting materials the same time with other materials from nozzle by laser. After solidification, the prototype layer forms. The parts will be made after overlapping layer by layer. DMD can create near net shape and controls heat input, which decreases post processing of the product.

DMD rapid prototyping allows us to monitor and control the height and temperature of the melt pool. Apyrometer monitor melt pool temperature which allows for consistency and is critical when depositing dissimilar or bimetallic metals. Furthermore, it controls the dilution of substrates, even though the deposited material and substrate material may have very different melting temperatures.

Due to its low prototyping precision but no limited prototyping space, it's often used for manufacturing large metal semi-finished components. Differ from conventional plating or coating,direct metal deposition china rapid prototyping technology also can prolong the lives of components by applying corrosion resistant coatings.

DMD is capable of processing medium to large size parts with multiple materials, which takes a significant competitive advantage over other additive metal manufacturing technologies such as DMLS and EBM.

Direct Metal Deposition