Quick Link

Find Products

Contact us

News

Home > News > Materials For CNC machined aluminum parts

Materials For CNC machined aluminum parts

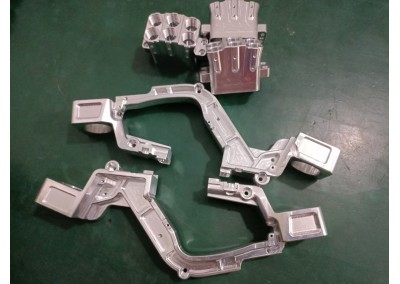

CNC machined aluminum parts are becoming great options for many industries. As one of the most popular materials, aluminum performs excellent mechanical properties. In terms of machining materials, CNC aluminum machined parts are the most economical as they can be used by CNC machining for a shorter time than other metals. Aluminum machined products also have added strength, corrosion, and rust resistance. Furthermore, aluminum machined parts are chemical resistant, electrically conductive, malleable, and possess high strength. Today, CNC machined aluminum parts are widely used in automotive, aerospace, military, medical, and industrial engineering.

Aluminum 2024

This grade is widely used in aerospace and military applications, as its high fatigue resistance, high strength, and susceptibility to thermal shocks.

Aluminum 5052

This is one of the most popular aluminum, due to its excellent mechanical properties and weldability, easy to anodize. Aluminum 6061 is also commonly used for extrusion, for its good toughness, medium to high strength, excellent corrosion resistance in harsh environments, easy anodization, and good workability.

Aluminum 6063

The grade performs excellent mechanical properties, such as easy weldability, heat treatability, and durability. This grade is commonly used for creating complex shapes with smooth surfaces and is commonly used in applications such as door frames, window frames, sign frames, roofs, etc.

Aluminum 7075

Another popular aluminum grade after 6061, aluminum 7075 is well-known for its excellent fatigue strength, which is most commonly used for tough components, such as aircraft wings, and fuselages, bicycle components, rock climbing equipment. AL7075 is also widely used as a reflector for automotive due to its better polish properties. This alloy has better corrosion resistance than the aluminum 2000 alloys.

Aluminum 2024

This grade is widely used in aerospace and military applications, as its high fatigue resistance, high strength, and susceptibility to thermal shocks.

Aluminum 5052

This is mostly used for sheet metal processes, as well as for building machine parts, and components to be used in saltwater environments. Aluminum 5052 offers good resistance to marine, saltwater, and industrial environments. The grade is easily punched, bent, and sheared into desired shapes.

This is one of the most popular aluminum, due to its excellent mechanical properties and weldability, easy to anodize. Aluminum 6061 is also commonly used for extrusion, for its good toughness, medium to high strength, excellent corrosion resistance in harsh environments, easy anodization, and good workability.

Aluminum 6063

The grade performs excellent mechanical properties, such as easy weldability, heat treatability, and durability. This grade is commonly used for creating complex shapes with smooth surfaces and is commonly used in applications such as door frames, window frames, sign frames, roofs, etc.

Aluminum 7075

Another popular aluminum grade after 6061, aluminum 7075 is well-known for its excellent fatigue strength, which is most commonly used for tough components, such as aircraft wings, and fuselages, bicycle components, rock climbing equipment. AL7075 is also widely used as a reflector for automotive due to its better polish properties. This alloy has better corrosion resistance than the aluminum 2000 alloys.