Quick Link

Find Products

Contact us

News

Home > News > Rapid prototyping in automotive industry

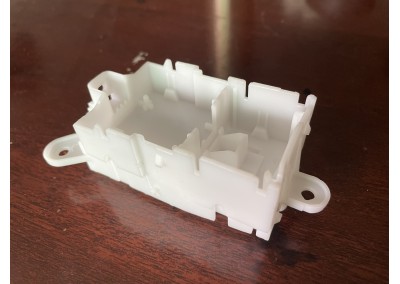

Rapid prototyping in automotive industry

What Is Automotive Prototype?

Automotive prototype is a sample car produced by automobile manufacturers during the development of new products. It is mainly used for various evaluation and performance tests of new products. After finding out the problems of the sample car and making modifications, the new round of sample car will be tested. In general, after a few rounds of trial production and testing of prototype vehicles, new products can be set up and put into production.

Automotive development is one typical example which small initial quantities are needed for validation procedures. This critical demand is no doubt great challenges for parts manufacturers. When client comes to order a few dozen pieces, it’s often hard to respond, which is why auto suppliers frequently have to turn to customed machined solutions. Traditional, long-lived standard tools are expensive and are generally not viable for small batch production situations that require only low-volume demands. Professional rapid prototyping companies tend to be the fastest to understand the needs of designers and provide customized machining services to meet the needs of small quantities or even a single part.

Including the structure & performance verification, automobile verification includes the visualizations of CAD digital model, design evaluation and interference inspection and even some functional test can be achieved by automotive prototyping method.

Rapid prototyping and manufacturing techniques are used to compare multiple designs in a short time, thus they help reduce the development time of the entire product development. Also, before formal standard tooling for production, there will be pre-series tooling for low volume production. Methods such as silicone tool and ALU tool are as bridge tool before production.

Professional rapid prototyping companies tend to be the fastest to understand the needs of designers before production, and they usually provide customized machining services to meet the needs of small quantities or even a single part.

Automotive prototype is a sample car produced by automobile manufacturers during the development of new products. It is mainly used for various evaluation and performance tests of new products. After finding out the problems of the sample car and making modifications, the new round of sample car will be tested. In general, after a few rounds of trial production and testing of prototype vehicles, new products can be set up and put into production.

Automotive development is one typical example which small initial quantities are needed for validation procedures. This critical demand is no doubt great challenges for parts manufacturers. When client comes to order a few dozen pieces, it’s often hard to respond, which is why auto suppliers frequently have to turn to customed machined solutions. Traditional, long-lived standard tools are expensive and are generally not viable for small batch production situations that require only low-volume demands. Professional rapid prototyping companies tend to be the fastest to understand the needs of designers and provide customized machining services to meet the needs of small quantities or even a single part.

Including the structure & performance verification, automobile verification includes the visualizations of CAD digital model, design evaluation and interference inspection and even some functional test can be achieved by automotive prototyping method.

Rapid prototyping and manufacturing techniques are used to compare multiple designs in a short time, thus they help reduce the development time of the entire product development. Also, before formal standard tooling for production, there will be pre-series tooling for low volume production. Methods such as silicone tool and ALU tool are as bridge tool before production.

Professional rapid prototyping companies tend to be the fastest to understand the needs of designers before production, and they usually provide customized machining services to meet the needs of small quantities or even a single part.