Quick Link

Find Products

Contact us

News

Home > News > Rapid prototyping in product development

Rapid prototyping in product development

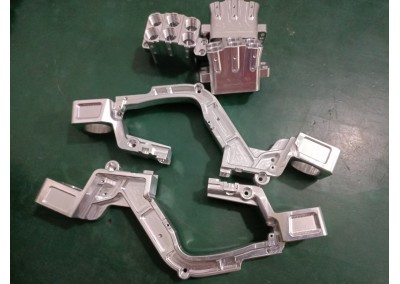

As the product development cycle has become more and more streamlined, the role of rapid prototyping has grown exponentially. Rapid prototyping is a process by which a prototype of a product is created quickly and efficiently, usually through the use of CNC machining or 3D printing technology. This allows for greater flexibility in the design process, as well as a quicker turnaround time from the prototype to the final product. Here are four aspects in which rapid prototyping technologies play a role in product development.

1. Proof Concept

The role of rapid prototyping in product development is to help businesses create a proof concept for their product. This is a prototype that is created quickly and inexpensively, so businesses can test their ideas in the early stages and make sure they are on the right track. Rapid prototyping allows businesses to have a market introduction early on in the product development process, which can help them make changes before they invest too much time and money into the project.

2. Visual Presentation

A product’s success often depends on its visual presentation. In the early stages of product development, it is important to create visuals that will accurately represent the product and its design. These visuals can help to communicate the product’s features and benefits to potential customers, as well as to stakeholders and prospective customers. Good visuals can also help to inspire and guide the product roadmaps and development process. By creating accurate, informative, and attractive visuals, product developers can create a strong foundation for a successful product.

Functional testing is a process of verifying that the individual sections of a product work as expected. It is usually one of the first types of testing to be conducted during the product development life cycle. The main goal of Functional Testing is to identify any defects in the functionality of the product. Functional Testing can be manual or automated. Manual Functional Testing is performed by testers who use test cases to verify just enough functionality of the product. Automated Functional Testing is performed by using special software tools that automate the testing process.

4. Engineering Validation

Engineering validation is a critical step in the product development process. It is used to ensure that products meet all of the requirements and specifications before they are released to customers. Engineering Validation includes testing and inspection of products, as well as reviews of design documents and feasibility analysis reports. It is important to ensure that products are properly validated so that customers can trust that they are getting what they expect. Engineering Validation helps to prevent product failures and ensures customer satisfaction.

1. Proof Concept

The role of rapid prototyping in product development is to help businesses create a proof concept for their product. This is a prototype that is created quickly and inexpensively, so businesses can test their ideas in the early stages and make sure they are on the right track. Rapid prototyping allows businesses to have a market introduction early on in the product development process, which can help them make changes before they invest too much time and money into the project.

2. Visual Presentation

A product’s success often depends on its visual presentation. In the early stages of product development, it is important to create visuals that will accurately represent the product and its design. These visuals can help to communicate the product’s features and benefits to potential customers, as well as to stakeholders and prospective customers. Good visuals can also help to inspire and guide the product roadmaps and development process. By creating accurate, informative, and attractive visuals, product developers can create a strong foundation for a successful product.

Functional testing is a process of verifying that the individual sections of a product work as expected. It is usually one of the first types of testing to be conducted during the product development life cycle. The main goal of Functional Testing is to identify any defects in the functionality of the product. Functional Testing can be manual or automated. Manual Functional Testing is performed by testers who use test cases to verify just enough functionality of the product. Automated Functional Testing is performed by using special software tools that automate the testing process.

4. Engineering Validation

Engineering validation is a critical step in the product development process. It is used to ensure that products meet all of the requirements and specifications before they are released to customers. Engineering Validation includes testing and inspection of products, as well as reviews of design documents and feasibility analysis reports. It is important to ensure that products are properly validated so that customers can trust that they are getting what they expect. Engineering Validation helps to prevent product failures and ensures customer satisfaction.