Quick Link

Find Products

Contact us

News

Home > News > Sheet Metal Prototyping Punching Process

Sheet Metal Prototyping Punching Process

At present, sheet metal prototyping punching is the most efficient method to produce precision fabricated metal components with many holes. Punching is often the cheapest way to create holes in sheet metal in medium to high production volumes.

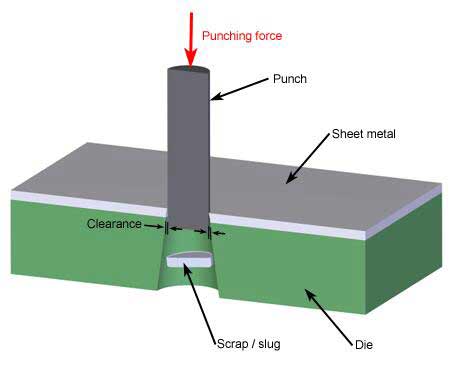

In order to obtain the desired shape of the metal, a machine is need to press a shape through a sheet of metal in the process of sheet metal prototyping punching.

By using a turret, a computer numerical controlled machine, the process will be done. The machine use pneumatic, hydraulic, or electrical power to press the shape with huge force to shear the metal sheet. The shape is formed by pressing the material against a die with enough force.

The shear forces generated between the material and die separate the material into the desired shape. But the desired shape can not be created because burred edges and rough surfaces are formed. These edges and surfaces must need further process until the desired shape is finally achieved.

Sheet Metal Prototyping Punching Process