Quick Link

Find Products

Contact us

News

Home > News > What is SLS rapid prototyping?

What is SLS rapid prototyping?

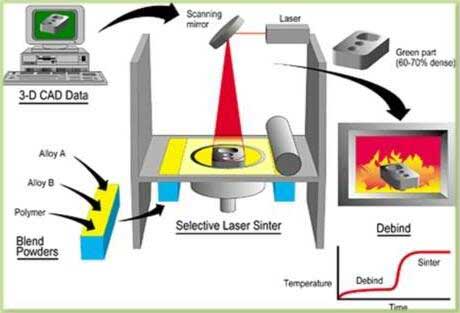

SLS(Selective Laser Sintering) is a technology based on rapid prototyping method. SLS uses a layer system of building up a part with each layer of powder being sintered separately by a laser.

As each layer is sintered, it slowly constructs the part step by step. There are all kinds of materials used to sinter according to their own features but they are sintered the same way inside the SLS machine. At present, China rapid prototyping materials include nylon and plastic powder. Metal powder is also used sometimes.

The SLS machine generally consists of 3 powder beds and a laser. Two of the powder beds hold the feed powder and the third bed holds the part. The part bed is middle of the beds with the laser acting directly perpendicular to this bed. A roller is used to push the layers of powder over the part bed and all three beds have their own heater source.

The sinter process is very simple but it needs repeat again and again. Take away the excessive powder after repeatable sinter and then grind and dry to get the rapid prototyping components.

SLS rapid prototyping process