Quick Link

Find Products

Contact us

News

Home > News > Who are some of the big users of rapid prototyping?

Who are some of the big users of rapid prototyping?

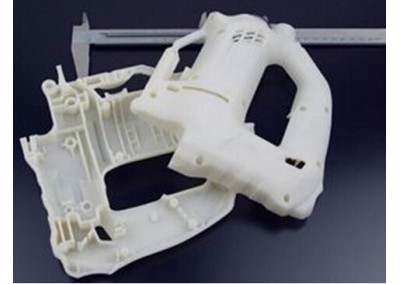

Rapid prototyping, also known as 3D printing, has become a valuable tool for a wide range of industries and organizations. Many big users of rapid prototyping come from the following sectors:

Aerospace: Aerospace companies use rapid prototyping to create and test components for aircraft, spacecraft, and satellites. This technology allows for the quick iteration of designs and the production of lightweight, complex parts.

Automotive: In the automotive industry, rapid prototyping is used for creating concept models, functional prototypes, and even some end-use parts. Car manufacturers benefit from faster design validation and cost savings.

Healthcare and Medical Devices: Medical professionals and device manufacturers utilize 3D printing for creating patient-specific implants, prosthetics, dental models, and custom medical devices. It allows for personalized healthcare solutions.

Consumer Electronics: Companies in the consumer electronics sector use rapid prototyping to design and test new product concepts. It aids in the development of sleek and ergonomic designs and quick product iterations.

Industrial Design and Product Development: Product design companies and manufacturers use 3D printing to create prototypes, test functional aspects, and validate the design of consumer and industrial products.

Jewelry and Fashion: Jewelry designers and fashion industry professionals use 3D printing to produce intricate, customized jewelry and accessories, pushing the boundaries of design.

Art and Sculpture: Artists and sculptors incorporate 3D printing into their creative processes, enabling them to produce complex and innovative sculptures and art installations.

Food and Culinary: Chefs and food technologists experiment with 3D printing to create artistic and customized food presentations, such as chocolates, pastries, and culinary decorations.

Energy and Oil & Gas: Companies in the energy and oil & gas sectors use 3D printing to manufacture complex components and parts for machinery, exploration equipment, and renewable energy projects.

Defense and Military: The military employs 3D printing for creating customized parts, tools, and prototypes, aiding in the rapid development of military hardware.

Custom Manufacturing and Small-Batch Production: Many small businesses and startups use 3D printing to produce customized and small-batch products, reducing production costs and time-to-market.

Aerospace: Aerospace companies use rapid prototyping to create and test components for aircraft, spacecraft, and satellites. This technology allows for the quick iteration of designs and the production of lightweight, complex parts.

Automotive: In the automotive industry, rapid prototyping is used for creating concept models, functional prototypes, and even some end-use parts. Car manufacturers benefit from faster design validation and cost savings.

Healthcare and Medical Devices: Medical professionals and device manufacturers utilize 3D printing for creating patient-specific implants, prosthetics, dental models, and custom medical devices. It allows for personalized healthcare solutions.

Consumer Electronics: Companies in the consumer electronics sector use rapid prototyping to design and test new product concepts. It aids in the development of sleek and ergonomic designs and quick product iterations.

Architecture and Construction: Architects and construction firms use 3D printing to create detailed architectural models, as well as to produce building components and prototypes of innovative construction materials.

Industrial Design and Product Development: Product design companies and manufacturers use 3D printing to create prototypes, test functional aspects, and validate the design of consumer and industrial products.

Jewelry and Fashion: Jewelry designers and fashion industry professionals use 3D printing to produce intricate, customized jewelry and accessories, pushing the boundaries of design.

Art and Sculpture: Artists and sculptors incorporate 3D printing into their creative processes, enabling them to produce complex and innovative sculptures and art installations.

Dental Laboratories: Dental labs use 3D printing for producing crowns, bridges, orthodontic devices, and dentures. This technology offers precision and customization in the dental field.

Food and Culinary: Chefs and food technologists experiment with 3D printing to create artistic and customized food presentations, such as chocolates, pastries, and culinary decorations.

Energy and Oil & Gas: Companies in the energy and oil & gas sectors use 3D printing to manufacture complex components and parts for machinery, exploration equipment, and renewable energy projects.

Defense and Military: The military employs 3D printing for creating customized parts, tools, and prototypes, aiding in the rapid development of military hardware.

Custom Manufacturing and Small-Batch Production: Many small businesses and startups use 3D printing to produce customized and small-batch products, reducing production costs and time-to-market.